+86 571 8373 7826

English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

OEM

Zechin industries

ISO9001

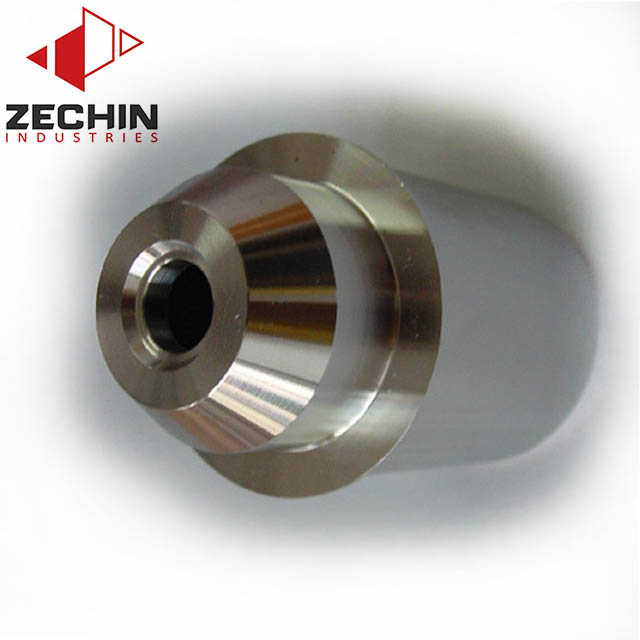

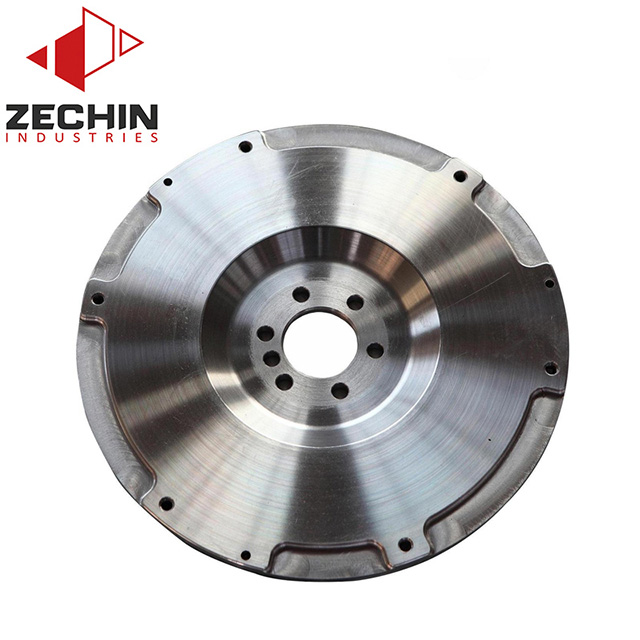

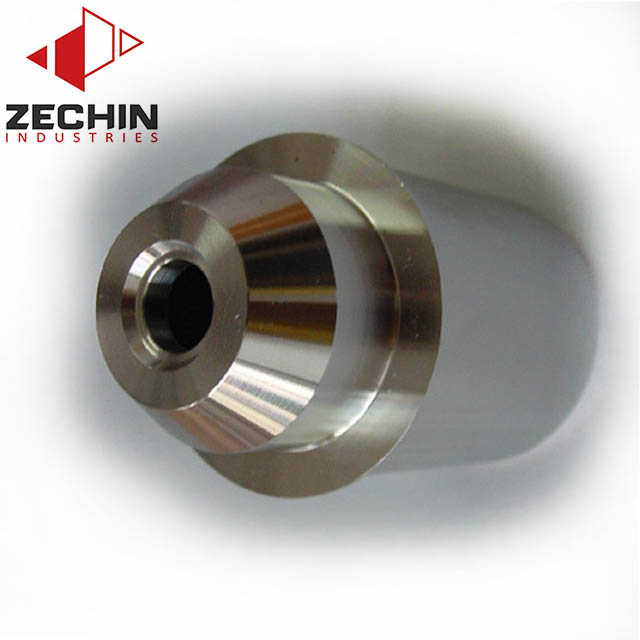

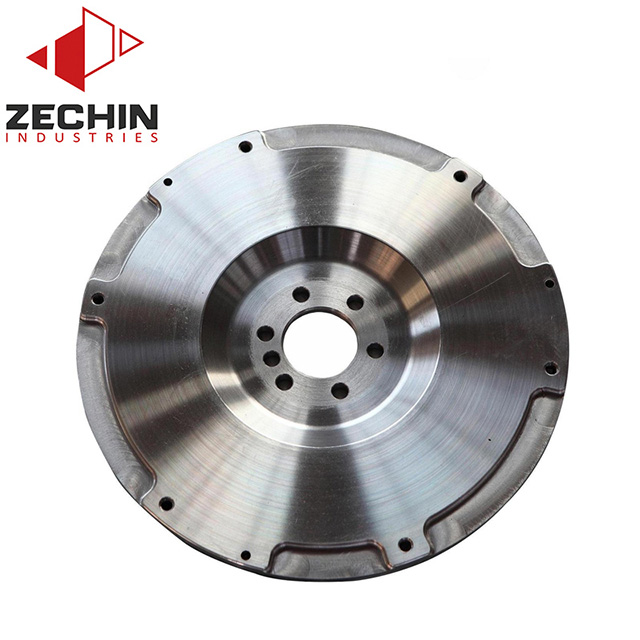

Cutting, Boring, milling, Broaching, Tapping, Grinding, Drilling, Knurling

Rust prevention, Plating, etc.

Standard Package or Customized

Shanghai / Ningbo

Prototype to High Quantity

Zhejiang, China (Mainland)

1, One-stop solution - Covering multiple machining processes

| Item Name | CNC Custom Milled metal machining parts service manufacturer |

| Tolerance | 0.02mm~0.1mm |

| Surface Roughness | Ra 0.8-Ra3.2 |

| DRW format | .jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Equipment | CNC Machining center, CNC Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine, polishing machine etc. |

| Capacity | 5,000pieces per month |

| MOQ | 50pcs for small parts;10pcs for big parts, according to your drawings |

| QC System | ISO |

| Payment term | T/T, PayPal, West Union,etc |

| Surface treatment | Anodizing, sandblasting,Powder Coating, zinc/chrome/nickel/silver/gold Plating, Polish, Nitriding, Blacking, Painting, Heat treatment etc |

| Other services | CNC engrave, Laser engrave, silk printing, Knurling |

| Shipment Terms: | 1) 0-500kg: air freight priority |

| 2) >500kg: sea freight priority | |

| 3) As per customized specifications | |

| Packing | 1. Prevent from damage. |

| 2. Foam and paper box or wooden box. | |

| 3. As to customers' requirements, in good condition | |

| Lead time | 15~25 days, as to your quantity |

1, Main Materials

Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416 etc. |

Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

Copper | C11000,C12000,C12000, C36000 etc. |

Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

Iron | A36, 45#, 1213, 12L14, 1215 etc. |

Plastic | ABS, PC, PE, POM, Nylon, PP, Peek etc. |

2, Surface Treatment

Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving |

Steel | Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated |

Aluminum parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing |

Plastic | Plating gold (ABS), Painting, Brushing (Acylic), laser engraving |

3, Application

• Agricultural equipment | • Armament | • Automobile industry | • Computing equipment |

• Medical / dental instruments | • Measuring instruments | • Miscellaneous equipment | • Pharmaceutical industry |

• Orthopedic implants | • Safety equipment | • Petrochemical industry | • Industrial valves |

•Fixing and movable equipment | • Sanitary fittings | • General machinery | • Pumps and general connections |

• Food and beverage processing | • Instrumentation equipment | • Pharmaceutical industry | • Textile equipment |

Zechin Industries is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

1. Q: Are you trading company or factory ? A: We are manufacturer with our own factory.Welcome to visit our factory.

2. Q: How can i get the quotation? What i need do before send the inquiry? A: 1). Please provide 2D drawings(PDF,DWG,DXF) or 3D files(STEP,STP,IGS). 2). Material required. 3). Surface finishing. 4). Quantity you need. 5). Other additional requirements.

3. Q:What can you customized? A: We can use many different technical processing methods to produce the projects that customers need, and we can customize any product. Specilized in CNC machining, CNC milling, CNC turning, Sheet metal, Also can customized Laser engraving, silk printing, CNC machining engraving, Etching.

4. Q:What should I do if received defective parts? A: If you received defective parts, or incorrect parts, please send products photos to us, we will feedback to our engineer teams and QC departments to solve the problem within 24 hours. Regardless of whether the product is damaged during transportation or due to production errors, we will re-produce for the customer and send it to the customer as soon as possible.

5.Q: What type packaging do you use for customer's products? A: For small and slight products, we will use standard export carton with soft plastic foam packaging. For big and weight products, we will cover soft plastic foam and then use thin films enwind it,finally pack into good quality wooden case shipment. Sure we will also package and transport according to customer requirements.

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

1, One-stop solution - Covering multiple machining processes

| Item Name | CNC Custom Milled metal machining parts service manufacturer |

| Tolerance | 0.02mm~0.1mm |

| Surface Roughness | Ra 0.8-Ra3.2 |

| DRW format | .jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Equipment | CNC Machining center, CNC Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine, polishing machine etc. |

| Capacity | 5,000pieces per month |

| MOQ | 50pcs for small parts;10pcs for big parts, according to your drawings |

| QC System | ISO |

| Payment term | T/T, PayPal, West Union,etc |

| Surface treatment | Anodizing, sandblasting,Powder Coating, zinc/chrome/nickel/silver/gold Plating, Polish, Nitriding, Blacking, Painting, Heat treatment etc |

| Other services | CNC engrave, Laser engrave, silk printing, Knurling |

| Shipment Terms: | 1) 0-500kg: air freight priority |

| 2) >500kg: sea freight priority | |

| 3) As per customized specifications | |

| Packing | 1. Prevent from damage. |

| 2. Foam and paper box or wooden box. | |

| 3. As to customers' requirements, in good condition | |

| Lead time | 15~25 days, as to your quantity |

1, Main Materials

Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416 etc. |

Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

Copper | C11000,C12000,C12000, C36000 etc. |

Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

Iron | A36, 45#, 1213, 12L14, 1215 etc. |

Plastic | ABS, PC, PE, POM, Nylon, PP, Peek etc. |

2, Surface Treatment

Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving |

Steel | Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated |

Aluminum parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing |

Plastic | Plating gold (ABS), Painting, Brushing (Acylic), laser engraving |

3, Application

• Agricultural equipment | • Armament | • Automobile industry | • Computing equipment |

• Medical / dental instruments | • Measuring instruments | • Miscellaneous equipment | • Pharmaceutical industry |

• Orthopedic implants | • Safety equipment | • Petrochemical industry | • Industrial valves |

•Fixing and movable equipment | • Sanitary fittings | • General machinery | • Pumps and general connections |

• Food and beverage processing | • Instrumentation equipment | • Pharmaceutical industry | • Textile equipment |

Zechin Industries is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

1. Q: Are you trading company or factory ? A: We are manufacturer with our own factory.Welcome to visit our factory.

2. Q: How can i get the quotation? What i need do before send the inquiry? A: 1). Please provide 2D drawings(PDF,DWG,DXF) or 3D files(STEP,STP,IGS). 2). Material required. 3). Surface finishing. 4). Quantity you need. 5). Other additional requirements.

3. Q:What can you customized? A: We can use many different technical processing methods to produce the projects that customers need, and we can customize any product. Specilized in CNC machining, CNC milling, CNC turning, Sheet metal, Also can customized Laser engraving, silk printing, CNC machining engraving, Etching.

4. Q:What should I do if received defective parts? A: If you received defective parts, or incorrect parts, please send products photos to us, we will feedback to our engineer teams and QC departments to solve the problem within 24 hours. Regardless of whether the product is damaged during transportation or due to production errors, we will re-produce for the customer and send it to the customer as soon as possible.

5.Q: What type packaging do you use for customer's products? A: For small and slight products, we will use standard export carton with soft plastic foam packaging. For big and weight products, we will cover soft plastic foam and then use thin films enwind it,finally pack into good quality wooden case shipment. Sure we will also package and transport according to customer requirements.

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com