+86 571 8373 7826

English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

OEM

Zechin Industries

ISO9001

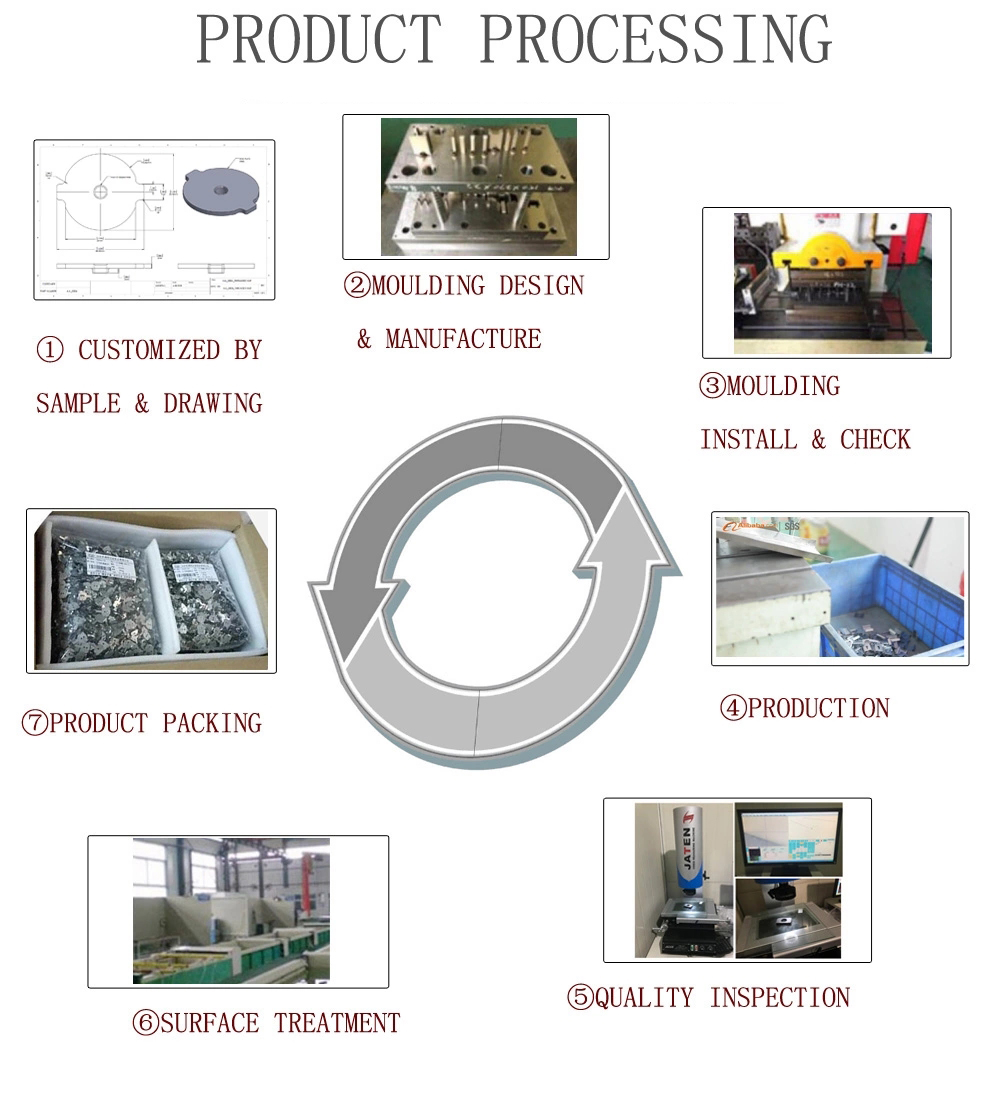

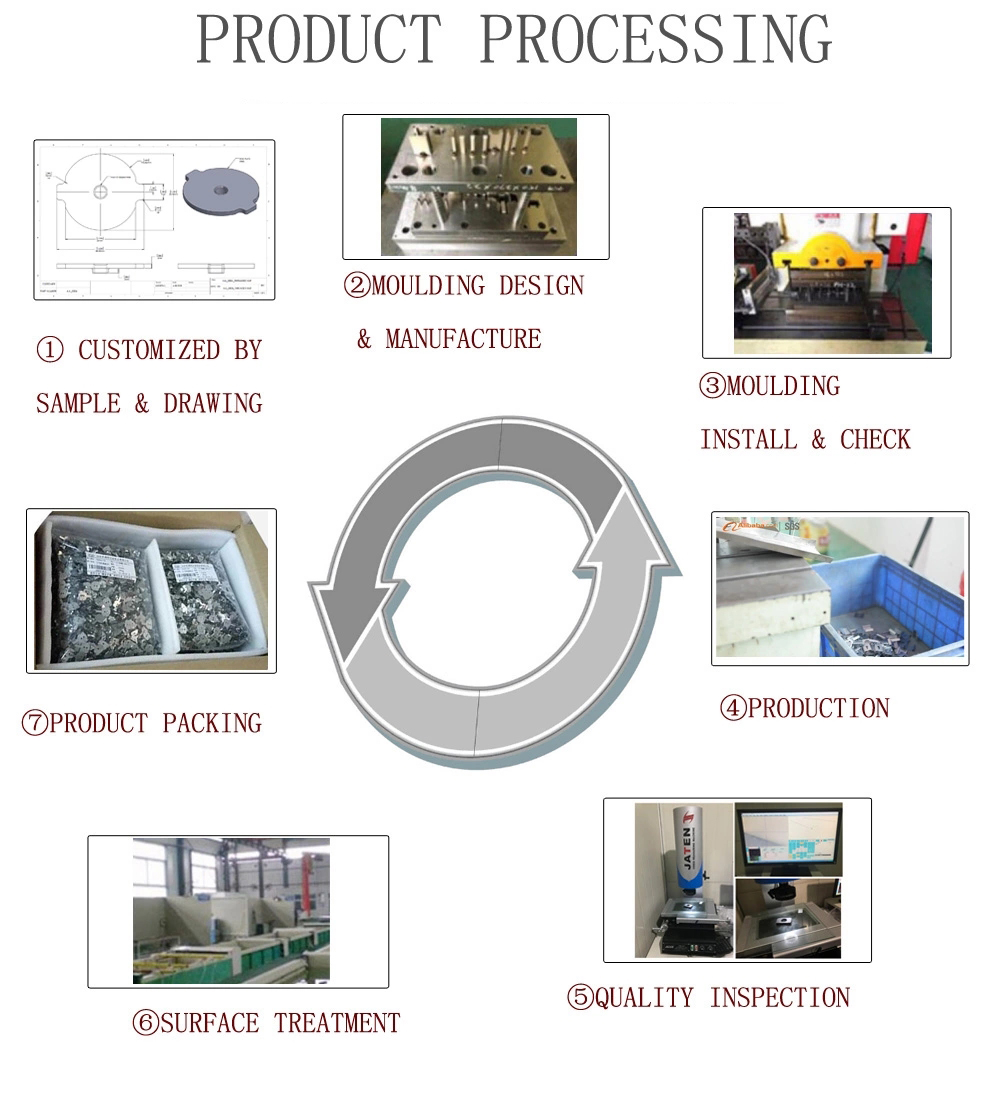

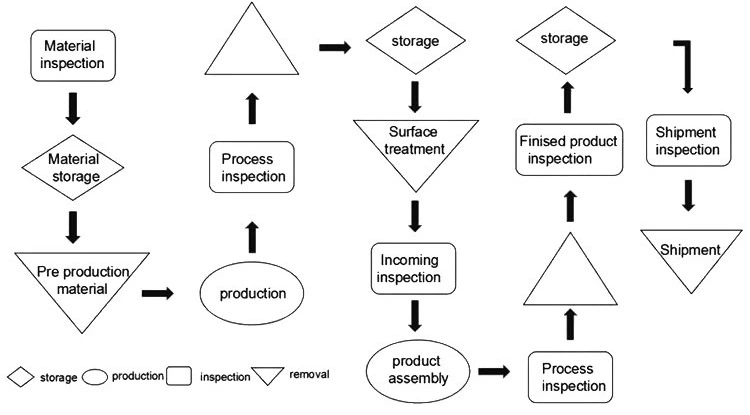

blanking, coining, bending, drawing, forming, piercing, Plating, Packing

Rust prevention, painting,powder coated, Plating, etc.

Standard Package or Customized

Shanghai / Ningbo

Prototype to High Quantity

Zhejiang, China (Mainland)

1. One-stop solution

2. Tools designed and built in house

3. Fully equipped & Trained

4. Consistent quality

5. Turnkey manufacturing services

6. Excellent communication ability

7. Professional & Efficient response

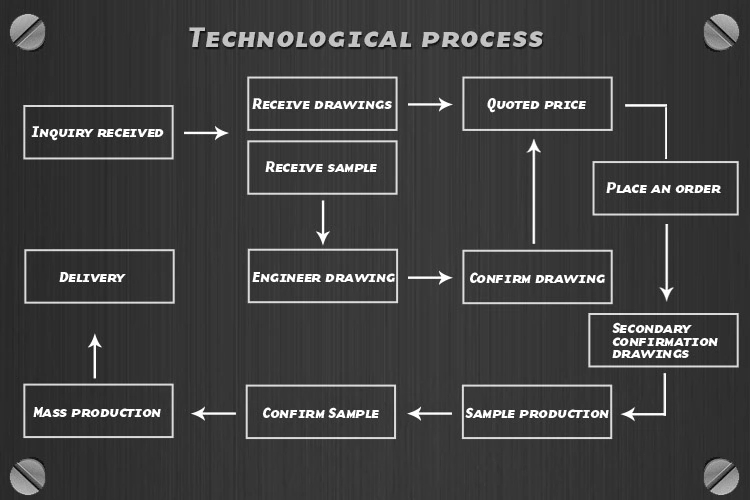

We use different type of stamping machine (cover from hand to precision punch)to produce metal stamping and pressing. According to customer's order quantity,we offer the most cost-effective way to your project, we can use laser cutting,Single-shot or continuous progressive die automated production.

Processing range: stamping, blanking, cutting, forming, rolling, welding, bending, flaring, bending tube, drilling, tapping, spot welding nuts or screws.

Pressing Capacity: 6.3-600 tons

Material : Metal, Stainless Steel, Brass, Copper, Aluminum, etc

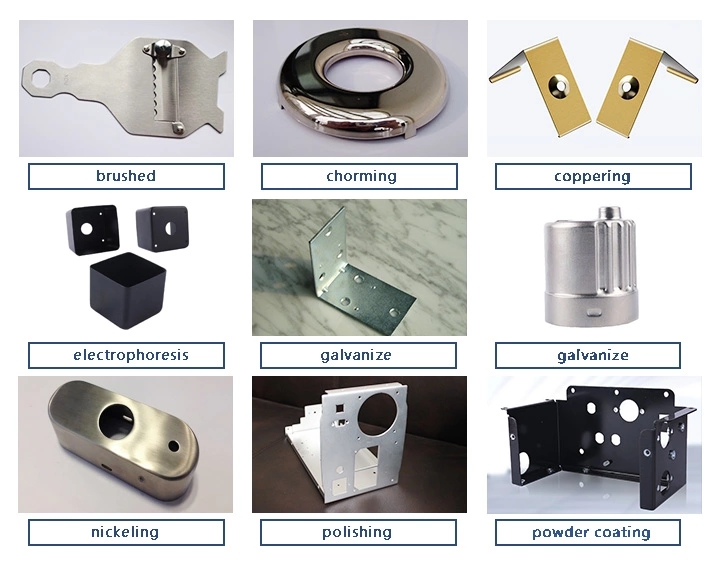

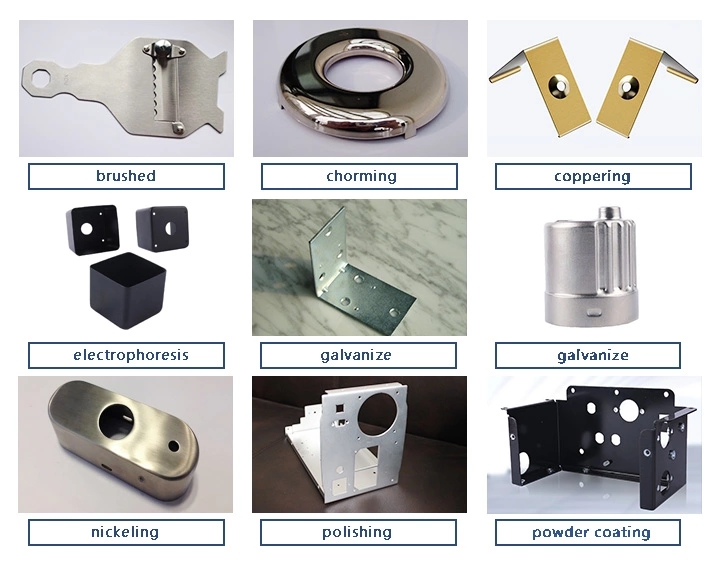

* Plating: Zinc, nickel, chromium, silver, etc.

* Anodized and Electrophoresis

* Paint and Powder

* Vibration deburring, polishing and chemical treatment

* Screen printing, color printing and laser engraving.

Surface Finish(for your reference):

| Aluminum Parts | Clear Anodized,Color Anodized,Sandblast Anodized,Polishing,Brushing,Chroming. |

| Steel Parts | Zinc plating,Nickel plating,Chrome plating,Oxide black,Heat treatment,Powder Coated |

| Stainless Steel Parts | Polishing,Passivating,Sandblasting,Laser engraving,Electrophoresis black,Oxide black. |

| Brass Parts | Zinc plating,Nickel plating,Chrome plating,Oxide black,Heat treatment,Powder Coated |

Product display

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

www.metalpartfabrications.com

1. One-stop solution

2. Tools designed and built in house

3. Fully equipped & Trained

4. Consistent quality

5. Turnkey manufacturing services

6. Excellent communication ability

7. Professional & Efficient response

We use different type of stamping machine (cover from hand to precision punch)to produce metal stamping and pressing. According to customer's order quantity,we offer the most cost-effective way to your project, we can use laser cutting,Single-shot or continuous progressive die automated production.

Processing range: stamping, blanking, cutting, forming, rolling, welding, bending, flaring, bending tube, drilling, tapping, spot welding nuts or screws.

Pressing Capacity: 6.3-600 tons

Material : Metal, Stainless Steel, Brass, Copper, Aluminum, etc

* Plating: Zinc, nickel, chromium, silver, etc.

* Anodized and Electrophoresis

* Paint and Powder

* Vibration deburring, polishing and chemical treatment

* Screen printing, color printing and laser engraving.

Surface Finish(for your reference):

| Aluminum Parts | Clear Anodized,Color Anodized,Sandblast Anodized,Polishing,Brushing,Chroming. |

| Steel Parts | Zinc plating,Nickel plating,Chrome plating,Oxide black,Heat treatment,Powder Coated |

| Stainless Steel Parts | Polishing,Passivating,Sandblasting,Laser engraving,Electrophoresis black,Oxide black. |

| Brass Parts | Zinc plating,Nickel plating,Chrome plating,Oxide black,Heat treatment,Powder Coated |

Product display

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

www.metalpartfabrications.com