+86 571 8373 7826

English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

OEM

Zechin Industries

ISO9001

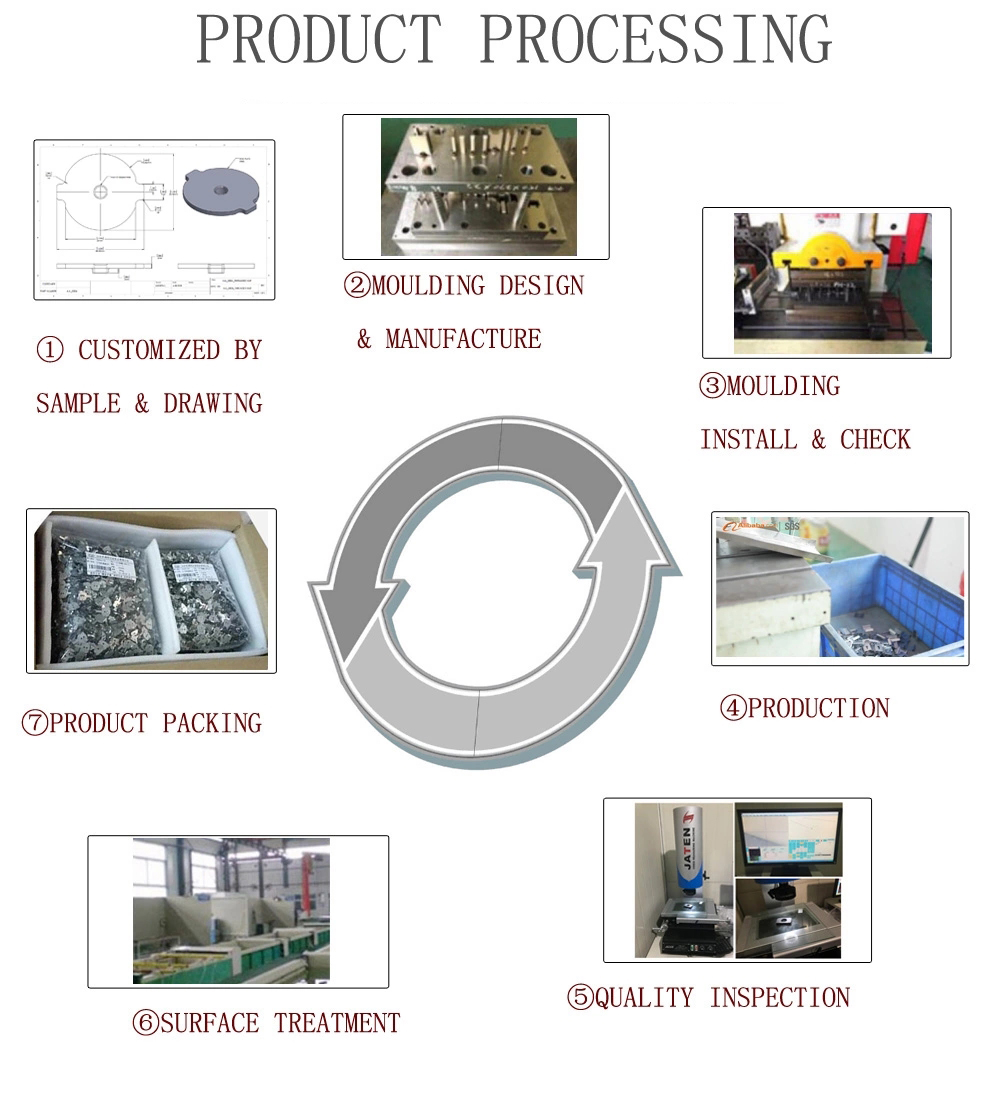

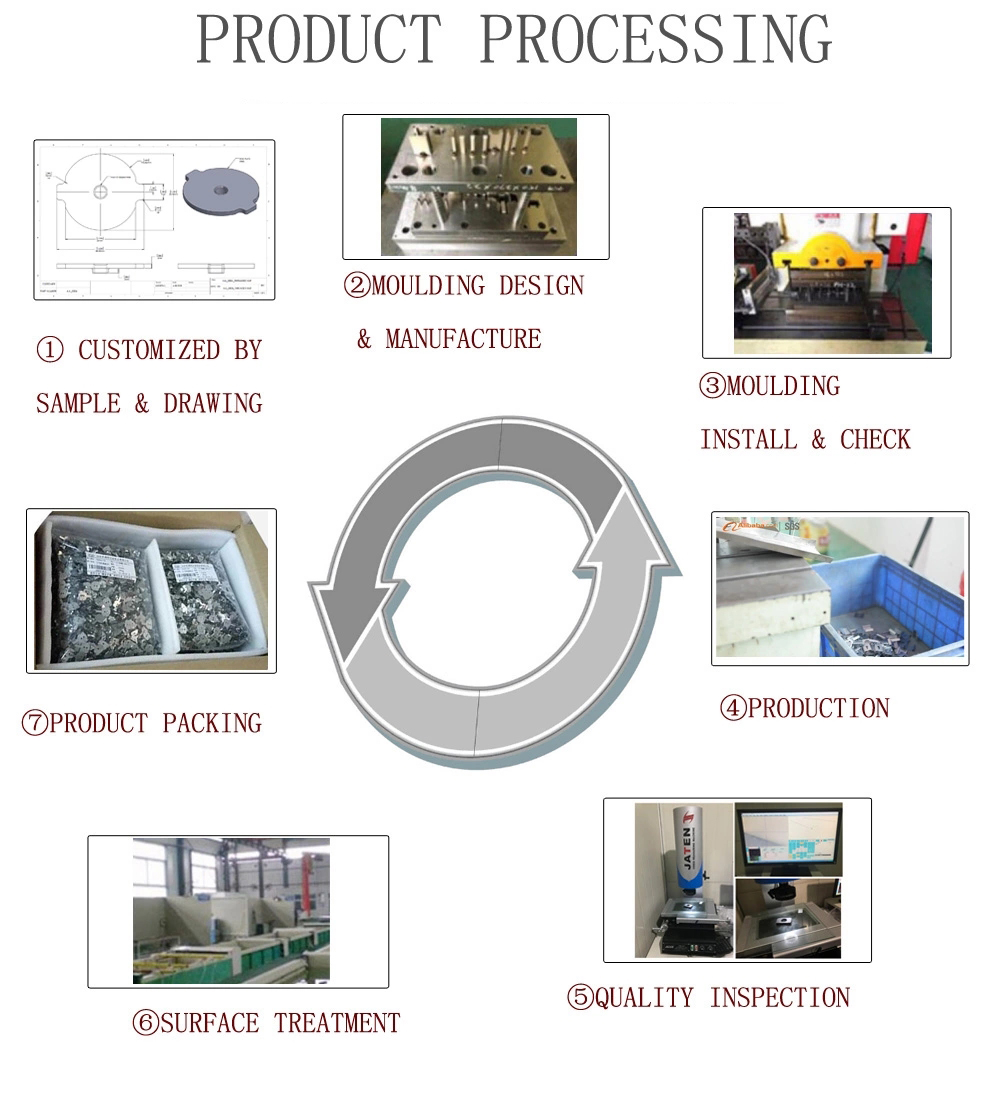

blanking, coining, bending, drawing, forming, piercing, Plating, Packing

Rust prevention, painting,powder coated, Plating, etc.

Standard Package or Customized

Shanghai / Ningbo

Prototype to High Quantity

Zhejiang, China (Mainland)

1. One-stop solution

2. Tools designed and built in house

3. Fully equipped & Trained

4. Consistent quality

5. Turnkey manufacturing services

6. Excellent communication ability

7. Professional & Efficient response

We use different type of stamping machine (cover from hand to precision punch)to produce metal stamping and pressing. According to customer's order quantity,we offer the most cost-effective way to your project, we can use laser cutting,Single-shot or continuous progressive die automated production.

Processing range: stamping, blanking, cutting, forming, rolling, welding, bending, flaring, bending tube, drilling, tapping, spot welding nuts or screws.

Pressing Capacity: 6.3-600 tons

Material : Metal, Stainless Steel, Brass, Copper, Aluminum, etc

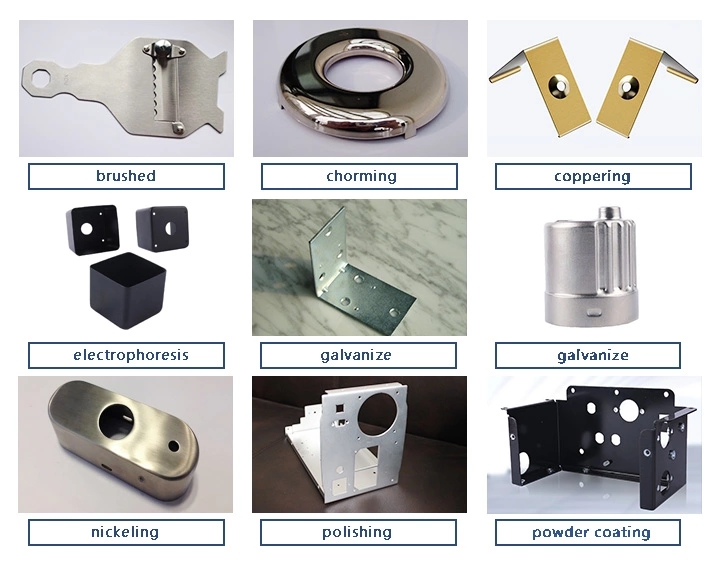

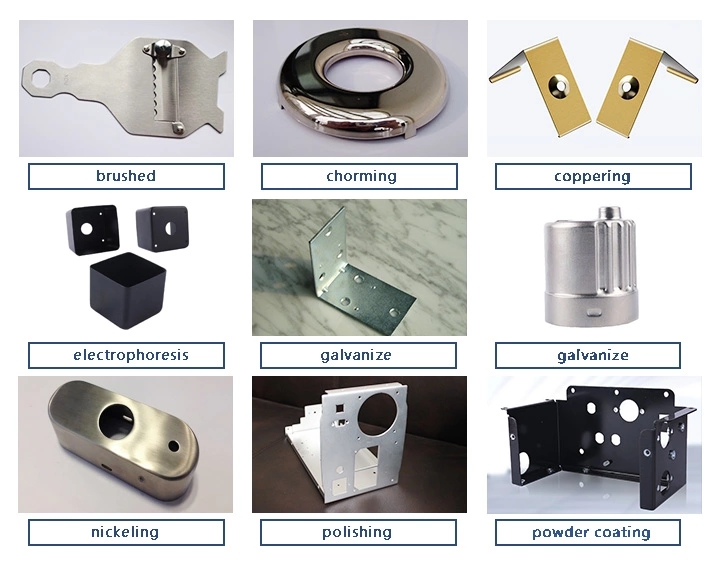

* Plating: Zinc, nickel, chromium, silver, etc.

* Anodized and Electrophoresis

* Paint and Powder

* Vibration deburring, polishing and chemical treatment

* Screen printing, color printing and laser engraving.

Surface Finish(for your reference):

| Aluminum Parts | Clear Anodized,Color Anodized,Sandblast Anodized,Polishing,Brushing,Chroming. |

| Steel Parts | Zinc plating,Nickel plating,Chrome plating,Oxide black,Heat treatment,Powder Coated |

| Stainless Steel Parts | Polishing,Passivating,Sandblasting,Laser engraving,Electrophoresis black,Oxide black. |

| Brass Parts | Zinc plating,Nickel plating,Chrome plating,Oxide black,Heat treatment,Powder Coated |

Product display

What’s behind the Zechin Industries advantage?

There are lots of reasons why the customer will want to try Zechin Industries and keep coming back.

Focus

To do make and supply the custom metal parts, that is the only one job for Zechin Industries in the past two decades and in the future.

Experience

Zechin Industries already has over than twenty years to supply the customized metal parts with our worldwide customers to accumulate profound knowledge, experience, practice and knowhow on the products, technology and export…………

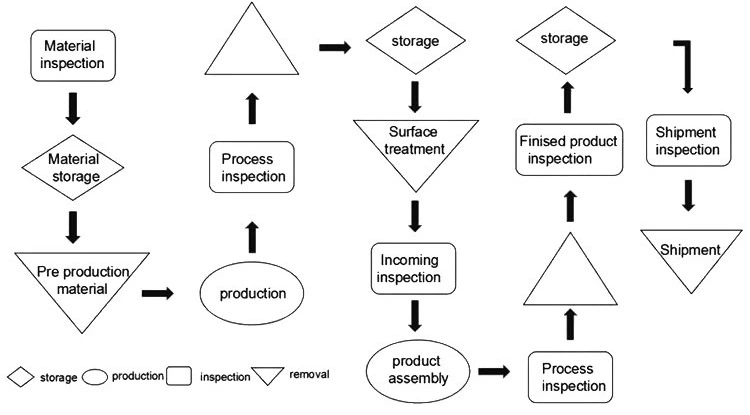

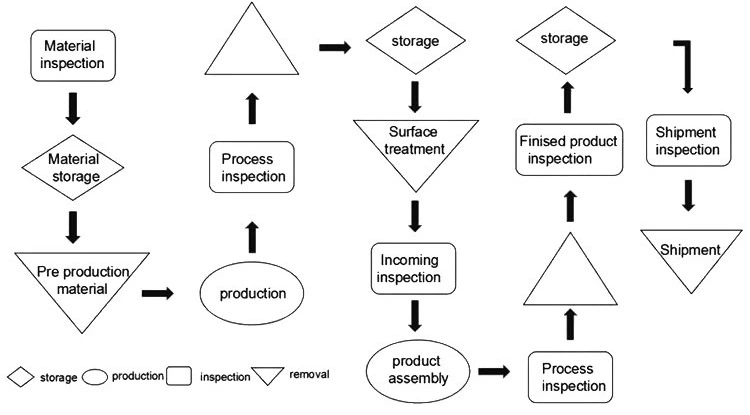

Quality guarantee

We manufacture the metal parts to know how to guarantee the quality. Then the skill inspectors from the QA & QC team at Zechin Industries factories will help our trading department to witness the product quality when we are behalf on you to purchase the parts with our qualified factories.

Cost control

Your requirements are understood and met the first time. To start from the quotation our team will assists you to procure an economical solution on the technique design under the no quality reduction condition. On the production stage, we monitor the cost………...

Repeatability

We can reproduce any design at any time thanks to well-documented production procedures.

Fast turnaround

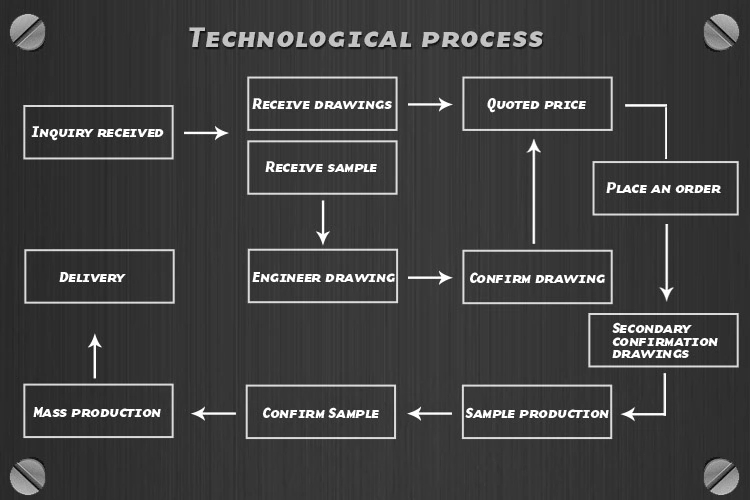

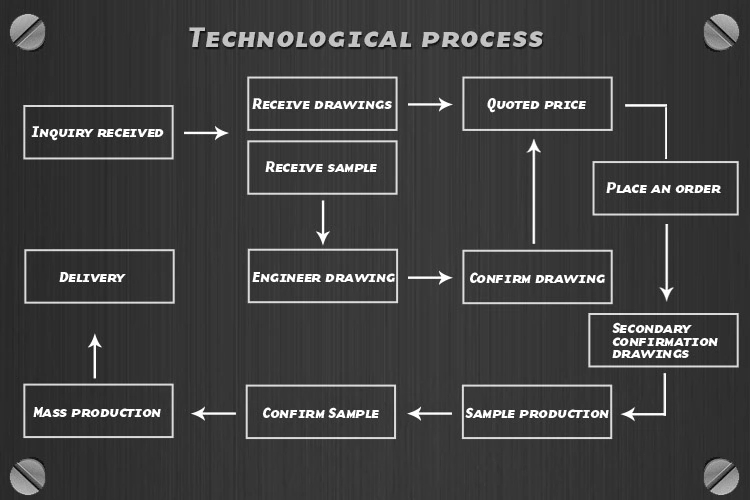

Every phase of our operation from quotation to production and shipment, we can do more efficient turnaround. We can often response within 24 hours.

Communication

Good-knowing background on the mechanical engineering plus skill English level, our international sales team could understand what your complete and exact meaning on your design and technical requirements. Thanks to the long term export business it is no problem for us to find out a proper equivalent GB with the popular international standards, such as ASTM, AISI, SAE, JIS, DIN, EN, ISO, BS........

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

www.metalpartfabrications.com

1. One-stop solution

2. Tools designed and built in house

3. Fully equipped & Trained

4. Consistent quality

5. Turnkey manufacturing services

6. Excellent communication ability

7. Professional & Efficient response

We use different type of stamping machine (cover from hand to precision punch)to produce metal stamping and pressing. According to customer's order quantity,we offer the most cost-effective way to your project, we can use laser cutting,Single-shot or continuous progressive die automated production.

Processing range: stamping, blanking, cutting, forming, rolling, welding, bending, flaring, bending tube, drilling, tapping, spot welding nuts or screws.

Pressing Capacity: 6.3-600 tons

Material : Metal, Stainless Steel, Brass, Copper, Aluminum, etc

* Plating: Zinc, nickel, chromium, silver, etc.

* Anodized and Electrophoresis

* Paint and Powder

* Vibration deburring, polishing and chemical treatment

* Screen printing, color printing and laser engraving.

Surface Finish(for your reference):

| Aluminum Parts | Clear Anodized,Color Anodized,Sandblast Anodized,Polishing,Brushing,Chroming. |

| Steel Parts | Zinc plating,Nickel plating,Chrome plating,Oxide black,Heat treatment,Powder Coated |

| Stainless Steel Parts | Polishing,Passivating,Sandblasting,Laser engraving,Electrophoresis black,Oxide black. |

| Brass Parts | Zinc plating,Nickel plating,Chrome plating,Oxide black,Heat treatment,Powder Coated |

Product display

What’s behind the Zechin Industries advantage?

There are lots of reasons why the customer will want to try Zechin Industries and keep coming back.

Focus

To do make and supply the custom metal parts, that is the only one job for Zechin Industries in the past two decades and in the future.

Experience

Zechin Industries already has over than twenty years to supply the customized metal parts with our worldwide customers to accumulate profound knowledge, experience, practice and knowhow on the products, technology and export…………

Quality guarantee

We manufacture the metal parts to know how to guarantee the quality. Then the skill inspectors from the QA & QC team at Zechin Industries factories will help our trading department to witness the product quality when we are behalf on you to purchase the parts with our qualified factories.

Cost control

Your requirements are understood and met the first time. To start from the quotation our team will assists you to procure an economical solution on the technique design under the no quality reduction condition. On the production stage, we monitor the cost………...

Repeatability

We can reproduce any design at any time thanks to well-documented production procedures.

Fast turnaround

Every phase of our operation from quotation to production and shipment, we can do more efficient turnaround. We can often response within 24 hours.

Communication

Good-knowing background on the mechanical engineering plus skill English level, our international sales team could understand what your complete and exact meaning on your design and technical requirements. Thanks to the long term export business it is no problem for us to find out a proper equivalent GB with the popular international standards, such as ASTM, AISI, SAE, JIS, DIN, EN, ISO, BS........

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

www.metalpartfabrications.com