+86 571 8373 7826

English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

OEM

Zechin industries

ISO9001

Blanking, Stamping, Forming, Deep drawing, Plating, Packing

Rust prevention, painting,powder coated, Plating, etc.

Standard Package or Customized

Shanghai / Ningbo

Prototype to High Quantity

Zhejiang, China (Mainland)

1.ODM&OEM service are all welcomed

2.Practicable Software: Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

3.Small orders accept

4.Reasonable and competitive price according to your drawings

Our Advantage:

1.Competitive price.

2.Continuance service and support.

3.Diversified rich experienced skilled workers.

4.Custom R&D program coordination.

5.Application expertise.

6.Quality,reliability and long product life.

7.Mature,perfect and excellence,but simple design.

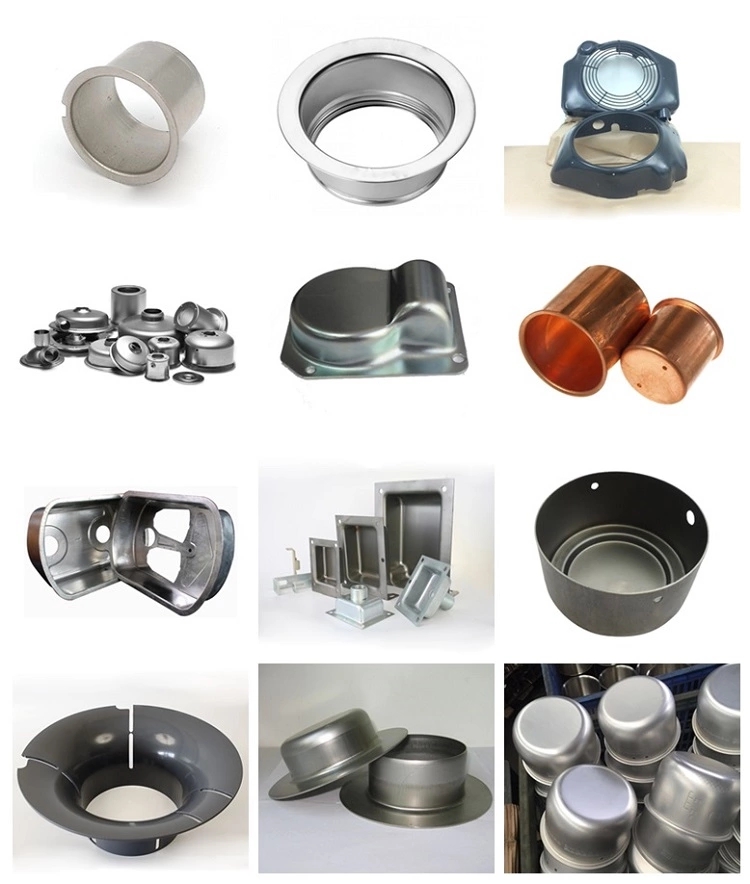

Product Name | Deep drawing parts custom sheet metal stampings |

Material | Aluminum,Carbon steel,Mild steel,Cold roll steel,Hot roll steel |

Thickness | 0.5mm-6mm |

Specification | Customized |

Working Process | stamping, deep stamping, bending, punching, threading,welding, tapping, riveting |

Drawing File | 2D:DWG,DXF,PDF |

Certificate | ISO SGS |

Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

Quality Control:

1) Technicians self-check in production

2) Engineer spot check in production

3) QC inspects after mass production finished

4) International sales who were trained the technical know-how spot check before shipping

In coming Quality control (IQC) – All incoming raw material are checked before used.

In process quality control (IPQC) – Perform inspections during the manufacturing process.

Final quality control (FQC) – – – – All finished goods are inspected according to our quality standard for

each products.

Outgoing Quality Control (OQC) – –Our QC team will do a final inspection before it goes out for

shipment.

Proper Quarantine procedure – For those products got rejected to pass the quality control, they will

specially marked and dispose.

Products applications:

Home appliance equipment, Auto parts, Industrial equipment, Electrical equipment, mechanical parts,

hardware parts,auto components,Computer electronics,Electronics components,Civil Engineering,Construction,Marine Industry,Garden Products,Military industry

Surface Treatments

Aluminum | Powder Coating, Brushing, Polishing, Sandblasting, Anodizing, PVD Plating, Nickel Plating, Chrome Plating, Bronze Plating, Copper Plating, Dacromet, Passivation |

Stainless Steel | Polishing, Brushing, PVD Plating, Nickel Plating, Chrome Plating, Powder Coating |

Carbon Steel | Powder Coating, Blackening, Baking Varnish, Dacromet, Zinc Plating, Hot Dip Galvanizing, Chrome Plating, Electrophoresis Coating, Enamel Painting, Heat Treatment etc. |

Spring Steel | Powder Coating, Zinc Plating, Tin-plating, Heat Treatment, Nickel Plating etc. |

Brass&Copper | Polishing, Brushing, Oil Injection, PVD Plating, Passivation etc. |

Secondary Operations

Surface Operations | · Deburring work by machines,then by hands; · As long as you need no scratches on the products, we can use the film protected material for products during production; · Remove sharps of the products · Ultrasonic cleaning after production; |

LOGO Printing | Laser Engraving, Silk-screening etc |

Packaging Customization | · Design packaging according to your products; · Make the packagings according to your requests; · Print your LOGO on the packaging as long as you need; · Other request according to your need. |

Why choose us?

1. High skilled and well-trained working team under good management environment.

2. Quick response and support for any inquiries.

3. Over 20 years professional manufacture experience to ensure high quality of your products.

4. Large and strong production capacity to meet your demand.

5. High Quality standard and hygienic environment.

6. We have very strict quality control process:

7. Good after sales services

8. Passed ISO 9001 and provide SGS/ RoHS certification if needed.

Contact Info:

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

1.ODM&OEM service are all welcomed

2.Practicable Software: Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

3.Small orders accept

4.Reasonable and competitive price according to your drawings

Our Advantage:

1.Competitive price.

2.Continuance service and support.

3.Diversified rich experienced skilled workers.

4.Custom R&D program coordination.

5.Application expertise.

6.Quality,reliability and long product life.

7.Mature,perfect and excellence,but simple design.

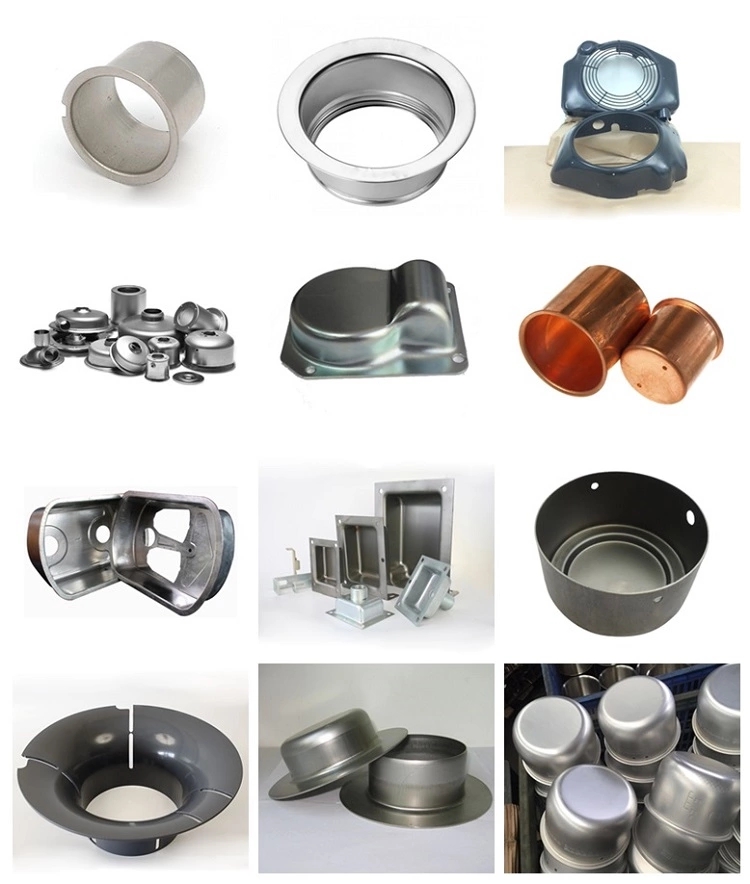

Product Name | Deep drawing parts custom sheet metal stampings |

Material | Aluminum,Carbon steel,Mild steel,Cold roll steel,Hot roll steel |

Thickness | 0.5mm-6mm |

Specification | Customized |

Working Process | stamping, deep stamping, bending, punching, threading,welding, tapping, riveting |

Drawing File | 2D:DWG,DXF,PDF |

Certificate | ISO SGS |

Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

Quality Control:

1) Technicians self-check in production

2) Engineer spot check in production

3) QC inspects after mass production finished

4) International sales who were trained the technical know-how spot check before shipping

In coming Quality control (IQC) – All incoming raw material are checked before used.

In process quality control (IPQC) – Perform inspections during the manufacturing process.

Final quality control (FQC) – – – – All finished goods are inspected according to our quality standard for

each products.

Outgoing Quality Control (OQC) – –Our QC team will do a final inspection before it goes out for

shipment.

Proper Quarantine procedure – For those products got rejected to pass the quality control, they will

specially marked and dispose.

Products applications:

Home appliance equipment, Auto parts, Industrial equipment, Electrical equipment, mechanical parts,

hardware parts,auto components,Computer electronics,Electronics components,Civil Engineering,Construction,Marine Industry,Garden Products,Military industry

Surface Treatments

Aluminum | Powder Coating, Brushing, Polishing, Sandblasting, Anodizing, PVD Plating, Nickel Plating, Chrome Plating, Bronze Plating, Copper Plating, Dacromet, Passivation |

Stainless Steel | Polishing, Brushing, PVD Plating, Nickel Plating, Chrome Plating, Powder Coating |

Carbon Steel | Powder Coating, Blackening, Baking Varnish, Dacromet, Zinc Plating, Hot Dip Galvanizing, Chrome Plating, Electrophoresis Coating, Enamel Painting, Heat Treatment etc. |

Spring Steel | Powder Coating, Zinc Plating, Tin-plating, Heat Treatment, Nickel Plating etc. |

Brass&Copper | Polishing, Brushing, Oil Injection, PVD Plating, Passivation etc. |

Secondary Operations

Surface Operations | · Deburring work by machines,then by hands; · As long as you need no scratches on the products, we can use the film protected material for products during production; · Remove sharps of the products · Ultrasonic cleaning after production; |

LOGO Printing | Laser Engraving, Silk-screening etc |

Packaging Customization | · Design packaging according to your products; · Make the packagings according to your requests; · Print your LOGO on the packaging as long as you need; · Other request according to your need. |

Why choose us?

1. High skilled and well-trained working team under good management environment.

2. Quick response and support for any inquiries.

3. Over 20 years professional manufacture experience to ensure high quality of your products.

4. Large and strong production capacity to meet your demand.

5. High Quality standard and hygienic environment.

6. We have very strict quality control process:

7. Good after sales services

8. Passed ISO 9001 and provide SGS/ RoHS certification if needed.

Contact Info:

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com