+86 571 8373 7826

English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

OEM

Zechin Industries

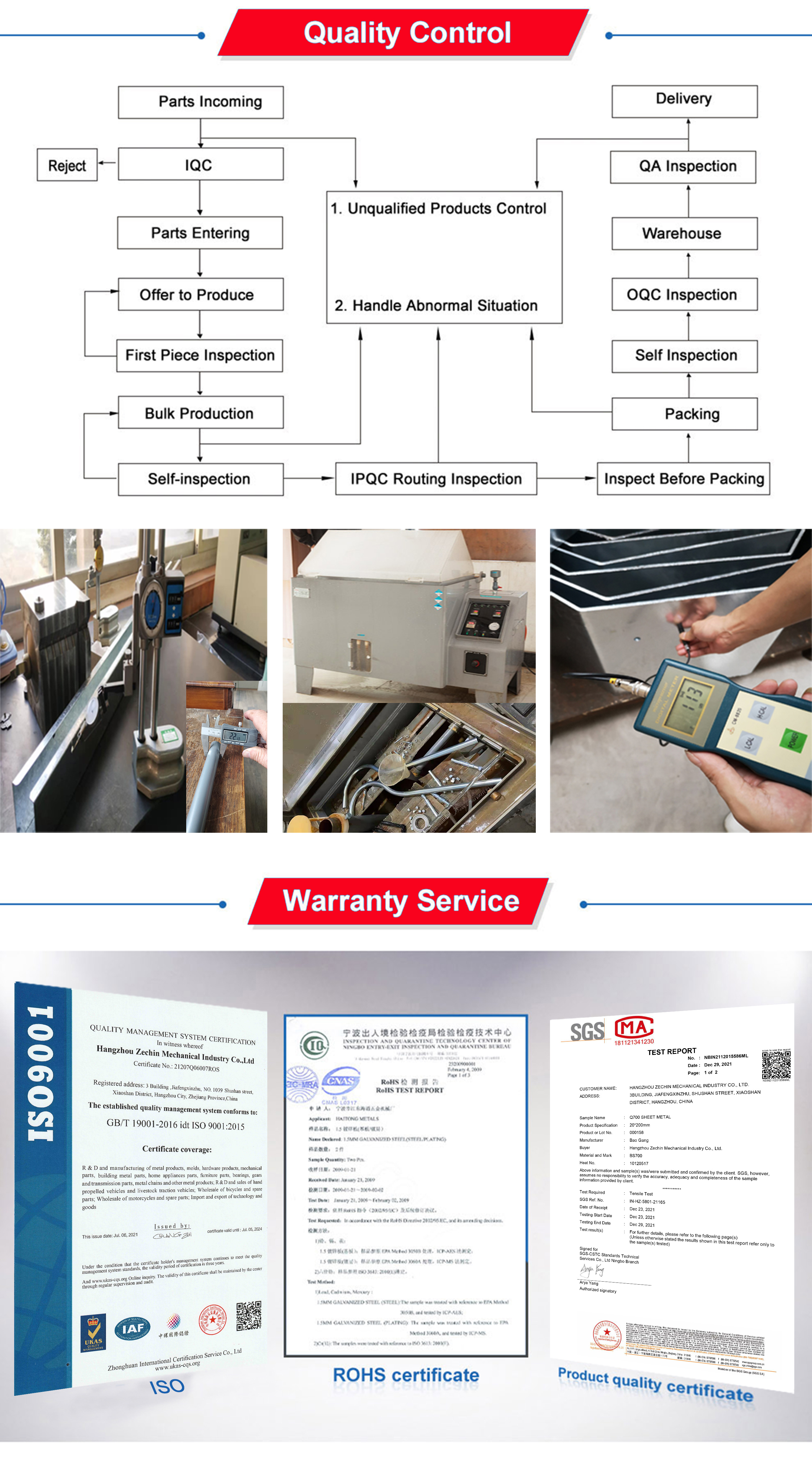

ISO9001

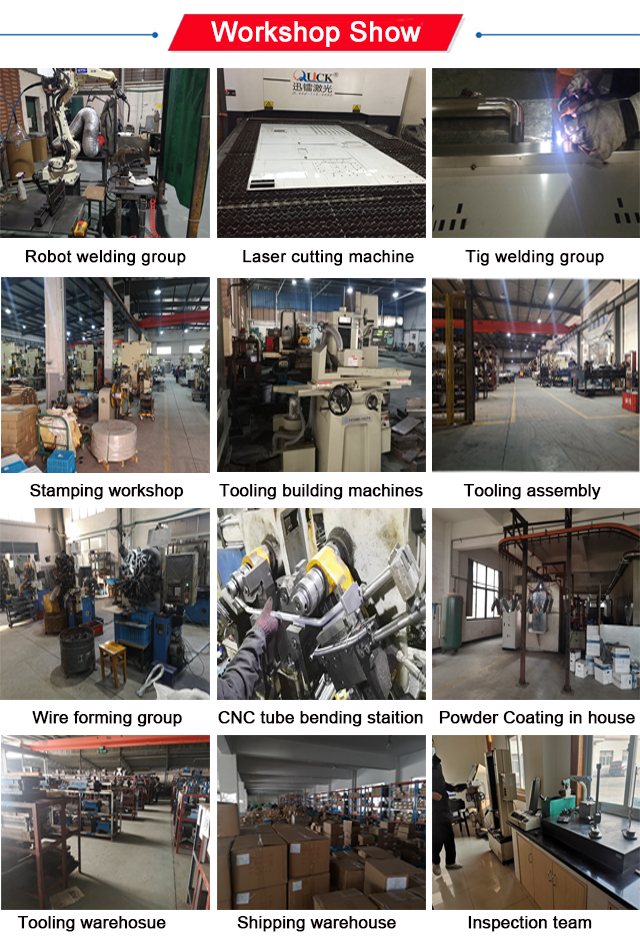

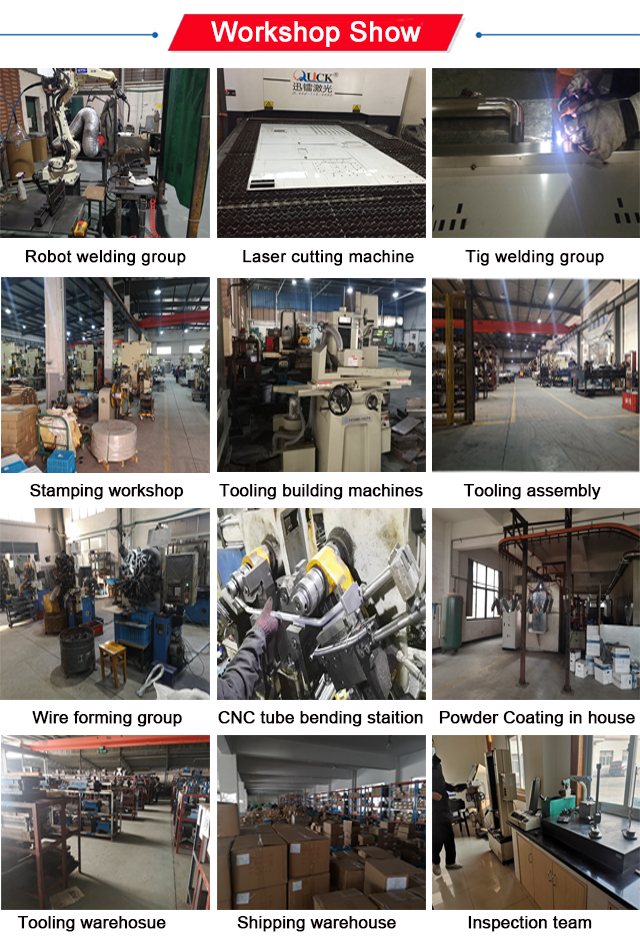

Cutting, bending, forming, dimple, drilling,/ welding

Rust prevention, painting,powder coated, Plating, etc.

Standard Package or Customized

Shanghai / Ningbo

Prototype to High Quantity

Zhejiang, China (Mainland)

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

About us for metal fabrication

a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

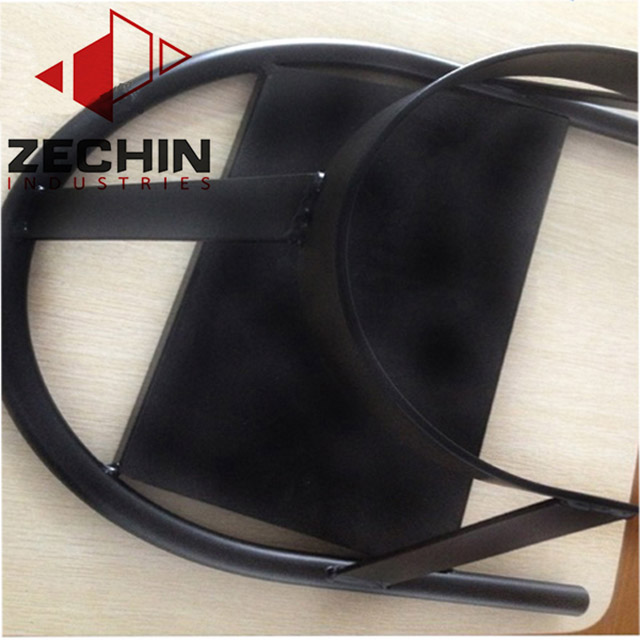

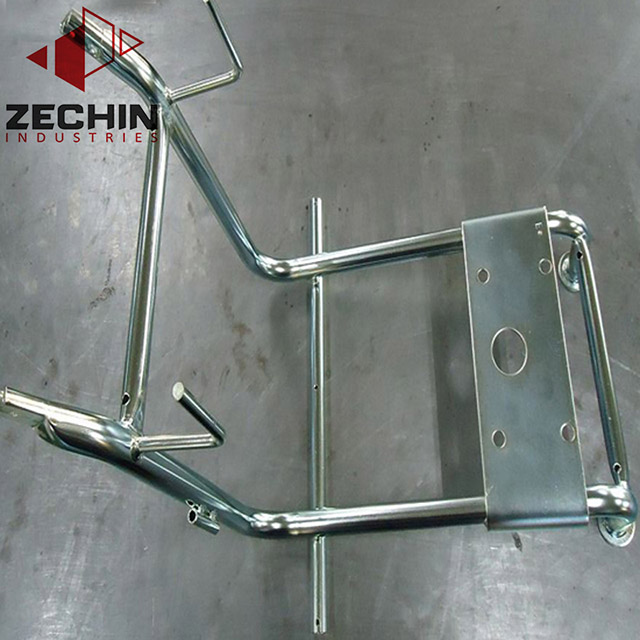

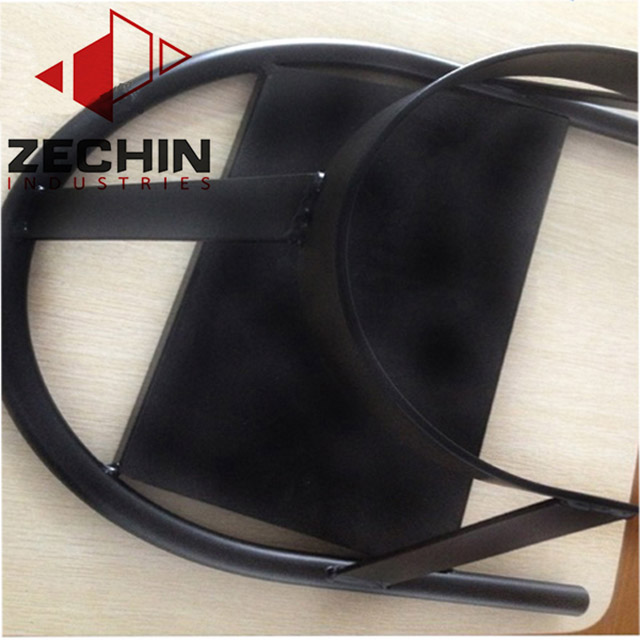

| Product Name | Lawn&garden tube bent metal stem handles |

| Color | according to customer's design |

| Normal Process | CNC Laser Cutting >Metal Bending > Welding and Polishing >Surface Treatment > Assembled Components and packaging. |

| Application | automobile, furniture, machine, electric, and other metal parts |

| Packing | Standard seaworthy packing or according to customer's request |

| Trade Terms | EXW, FOB, CIF, C&F, etc |

| Payment Terms | TT, L/C,Western Union,paypal |

Material available | Carbon steel (CRS/SPCC, SECC,etc),Stainless steel, spring steel, Bronze (berylium, phosphor, etc), brass, copper alloy, aluminum alloy, tinplate, nickel silver, cold roll steel, hot roll steel, zinc plate, etc. |

Metal processing available | Drilling, tapping, CNC finishing, CNC laser cutting, flame cutting, punching, stamping, pressing-folding, bending-welding-CNC machining, drilling-welding-spray, tapping, bending and forming,coating-assembling-packing |

Surface Finish: | Powder Coated, Hot Galvanized, Painting, Polishing, spray coating, Brushing, Cataphoresis, sandblasting, electroplate Chrome/Zinc/Nickel Plating/Anodize/Electronic Polish, Silk-screen etc; |

Specification | OEM/ODM, according to customer's drawing or sample |

Files Formats: | Pro/Engineer, Solidworks, Auto CAD, PDF |

Major Equipment: | TRUMPF LASER CUTTING MACHINE; |

CNC SHEAR MACHINE; | |

CNC PUNCHING MACHINE; | |

CNC BENDING MACHINE; | |

TIG WELDING MACHINE; | |

MIG WELDING MACHINE; | |

SPOT WELDING MACHINE; | |

RIVETING MACHINE | |

STAMPING MACHINE; | |

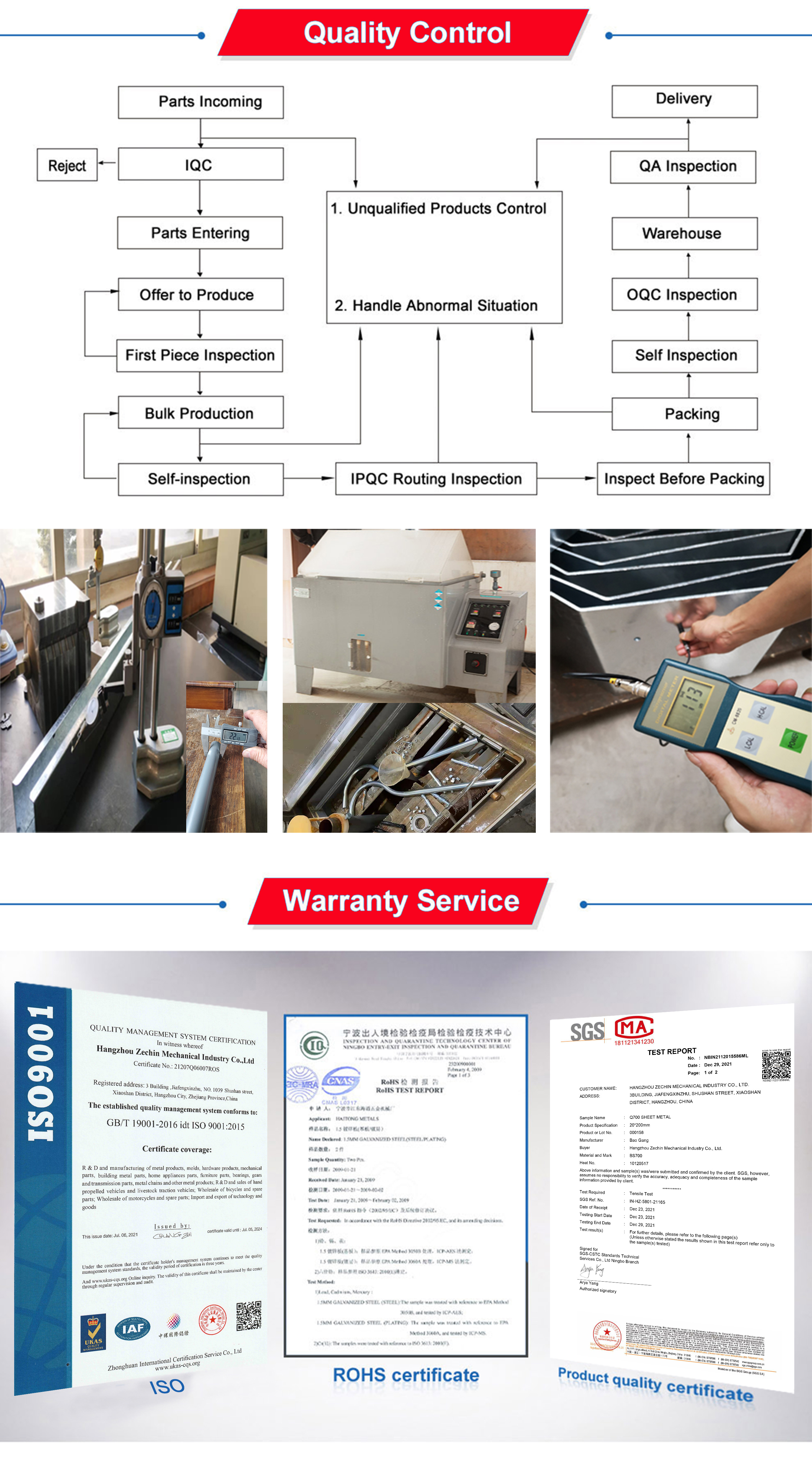

Detection method | Height gauge rule, slide calliper rule,vernier caliper, microcalliper,goniometer,sclerometer,colorimeter,etc. |

Our factory is a market leading provider of Metal Stamping, precision stamping metalwork, CNC Punching, Metal Welding, Deep Drawing, Bending, Sheet Metal Fabrication, Laser Cutting, Tool and Die Work, etc, the factory has grown in size and experience. From design through to full production, we are committed to high quality products and service. We are supplying many enterprises in World Top 500 and work together with many customers in Europe and USA.

Packing Method | Cartons and fumigation-free wooden box |

Transportation Method | Vessels/Air |

Loading Port | Shanghai / Ningbo |

Delivery Term | Generally speaking, we finish the molds within 20 to 35 days and deliver bulk production within 25 to 35 days. |

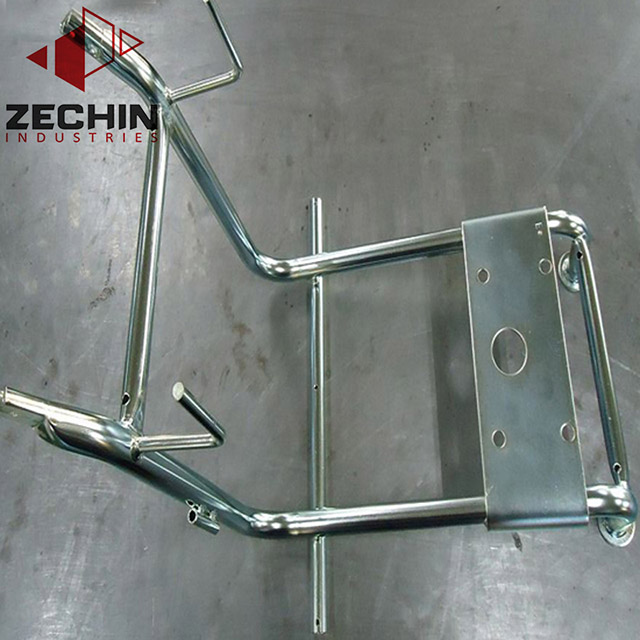

Product display

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

| Description | Lawn&garden tube bent metal stem handles |

| Materials Used | mild steel, stainless steel, aluminum (material specific series and grade as per customer required) |

| Available Finishes | polishing, zinc plating, electro polishing, anodizing, powder coating and etc. |

| Certificate | ISO9001 |

| Application | metal tube frame, metal rack, mower part and so on |

| Process | tube bending, tube welding, tube forming, tube fabrication |

| Dimensions | strictly as per customers' drawings |

| Service Capability | one stop custom metal parts fabrication service capability |

| Cooperation Model | OEM or ODM |

| Design | As per customers specific requirements or customers give us specific sample; or customers' conceptual or preliminary design; or customer sketched ideas. |

| Acceptable Drawing Format | jpg/ .dwg/ .igs/ .stp etc. |

| Application Material Standard | If no any specially required by customers, we usually suggest our customers to try the equivalent China National (GB) standard material that our engineer team proposes which to be properly converted from ANSI, ASTM, SAE, EN, DIN, BS, JIS and etc., to contribute the material cost control. |

| Aviailable Processing | shearing; crimping; laser cutting; bending; stamping; pressing; deep drawing; rolling; forming; fabricating; drilling; tapping; riveting; sopt welding; TIG; assembling |

| Precision | Average level: ±0.1mm, depending on product's size, thickness and material |

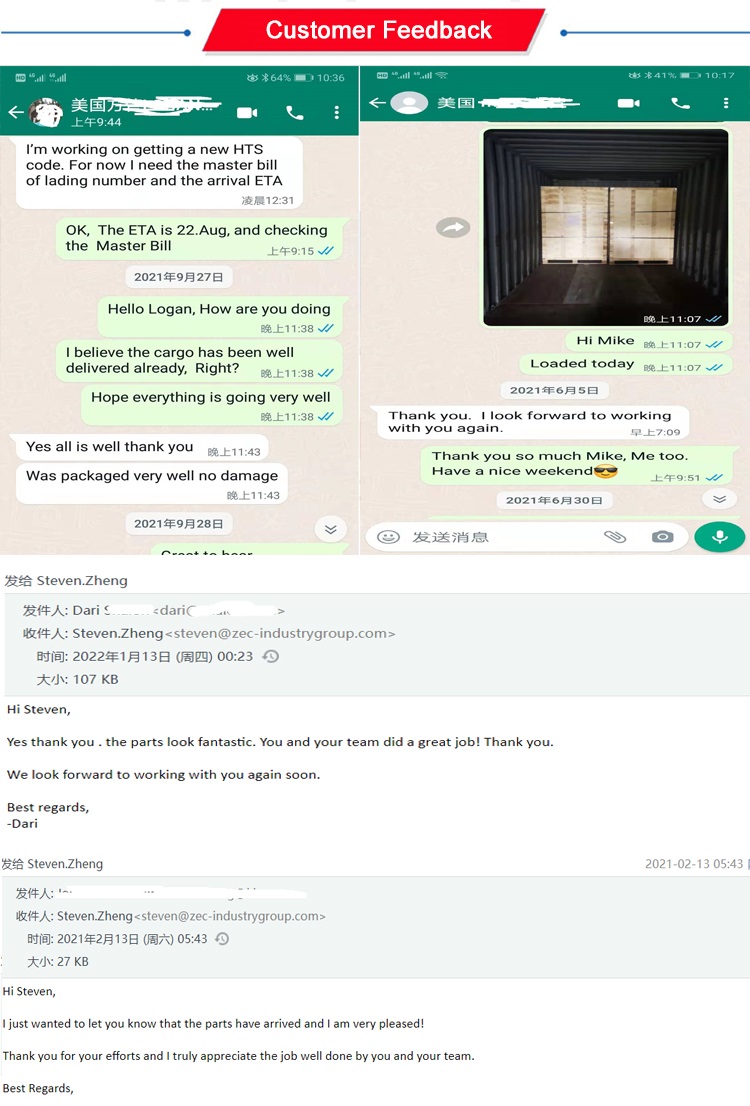

Notes:

products on website are just for reference and our promotion purpose only

we could provide similar products' custom fabrication service as per drawings

any questions about our custom service, please feel free to contact us and we will reply in details within 8 hours

Your drawings are warmly welcomed

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

www.metalpartfabrications.com

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

About us for metal fabrication

a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

| Product Name | Lawn&garden tube bent metal stem handles |

| Color | according to customer's design |

| Normal Process | CNC Laser Cutting >Metal Bending > Welding and Polishing >Surface Treatment > Assembled Components and packaging. |

| Application | automobile, furniture, machine, electric, and other metal parts |

| Packing | Standard seaworthy packing or according to customer's request |

| Trade Terms | EXW, FOB, CIF, C&F, etc |

| Payment Terms | TT, L/C,Western Union,paypal |

Material available | Carbon steel (CRS/SPCC, SECC,etc),Stainless steel, spring steel, Bronze (berylium, phosphor, etc), brass, copper alloy, aluminum alloy, tinplate, nickel silver, cold roll steel, hot roll steel, zinc plate, etc. |

Metal processing available | Drilling, tapping, CNC finishing, CNC laser cutting, flame cutting, punching, stamping, pressing-folding, bending-welding-CNC machining, drilling-welding-spray, tapping, bending and forming,coating-assembling-packing |

Surface Finish: | Powder Coated, Hot Galvanized, Painting, Polishing, spray coating, Brushing, Cataphoresis, sandblasting, electroplate Chrome/Zinc/Nickel Plating/Anodize/Electronic Polish, Silk-screen etc; |

Specification | OEM/ODM, according to customer's drawing or sample |

Files Formats: | Pro/Engineer, Solidworks, Auto CAD, PDF |

Major Equipment: | TRUMPF LASER CUTTING MACHINE; |

CNC SHEAR MACHINE; | |

CNC PUNCHING MACHINE; | |

CNC BENDING MACHINE; | |

TIG WELDING MACHINE; | |

MIG WELDING MACHINE; | |

SPOT WELDING MACHINE; | |

RIVETING MACHINE | |

STAMPING MACHINE; | |

Detection method | Height gauge rule, slide calliper rule,vernier caliper, microcalliper,goniometer,sclerometer,colorimeter,etc. |

Our factory is a market leading provider of Metal Stamping, precision stamping metalwork, CNC Punching, Metal Welding, Deep Drawing, Bending, Sheet Metal Fabrication, Laser Cutting, Tool and Die Work, etc, the factory has grown in size and experience. From design through to full production, we are committed to high quality products and service. We are supplying many enterprises in World Top 500 and work together with many customers in Europe and USA.

Packing Method | Cartons and fumigation-free wooden box |

Transportation Method | Vessels/Air |

Loading Port | Shanghai / Ningbo |

Delivery Term | Generally speaking, we finish the molds within 20 to 35 days and deliver bulk production within 25 to 35 days. |

Product display

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

| Description | Lawn&garden tube bent metal stem handles |

| Materials Used | mild steel, stainless steel, aluminum (material specific series and grade as per customer required) |

| Available Finishes | polishing, zinc plating, electro polishing, anodizing, powder coating and etc. |

| Certificate | ISO9001 |

| Application | metal tube frame, metal rack, mower part and so on |

| Process | tube bending, tube welding, tube forming, tube fabrication |

| Dimensions | strictly as per customers' drawings |

| Service Capability | one stop custom metal parts fabrication service capability |

| Cooperation Model | OEM or ODM |

| Design | As per customers specific requirements or customers give us specific sample; or customers' conceptual or preliminary design; or customer sketched ideas. |

| Acceptable Drawing Format | jpg/ .dwg/ .igs/ .stp etc. |

| Application Material Standard | If no any specially required by customers, we usually suggest our customers to try the equivalent China National (GB) standard material that our engineer team proposes which to be properly converted from ANSI, ASTM, SAE, EN, DIN, BS, JIS and etc., to contribute the material cost control. |

| Aviailable Processing | shearing; crimping; laser cutting; bending; stamping; pressing; deep drawing; rolling; forming; fabricating; drilling; tapping; riveting; sopt welding; TIG; assembling |

| Precision | Average level: ±0.1mm, depending on product's size, thickness and material |

Notes:

products on website are just for reference and our promotion purpose only

we could provide similar products' custom fabrication service as per drawings

any questions about our custom service, please feel free to contact us and we will reply in details within 8 hours

Your drawings are warmly welcomed

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

www.metalpartfabrications.com