+86 571 8373 7826

English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

OEM

Zechin Industries

ISO9001

Cutting, bending, forming, dimple, drilling, welding

Rust prevention, painting,powder coated, Plating, etc.

Standard Package or Customized

Shanghai / Ningbo

Prototype to High Quantity volume

Zhejiang, China (Mainland)

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

Our advantage for metal fabrication

a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

| Materials: | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

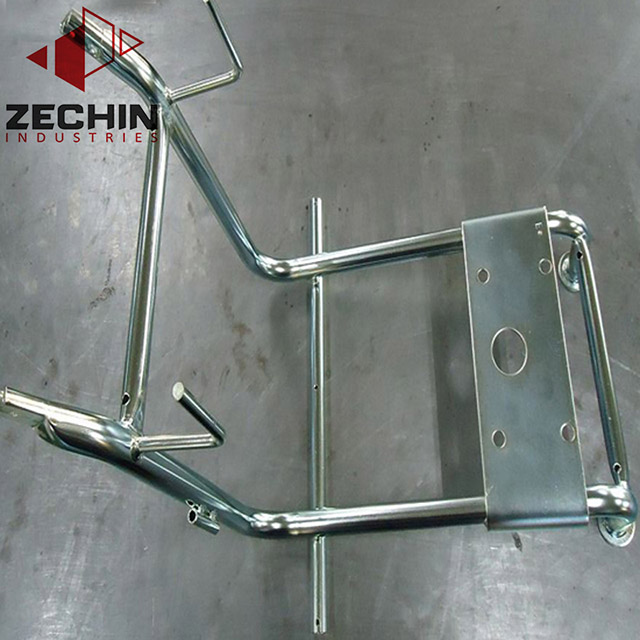

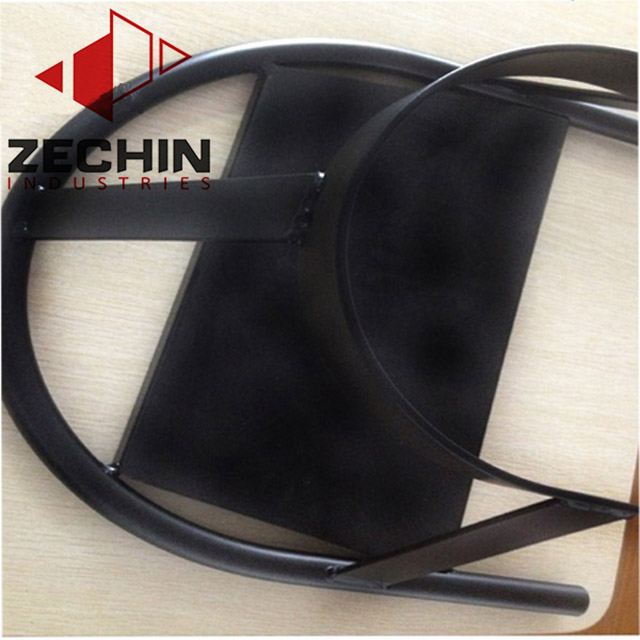

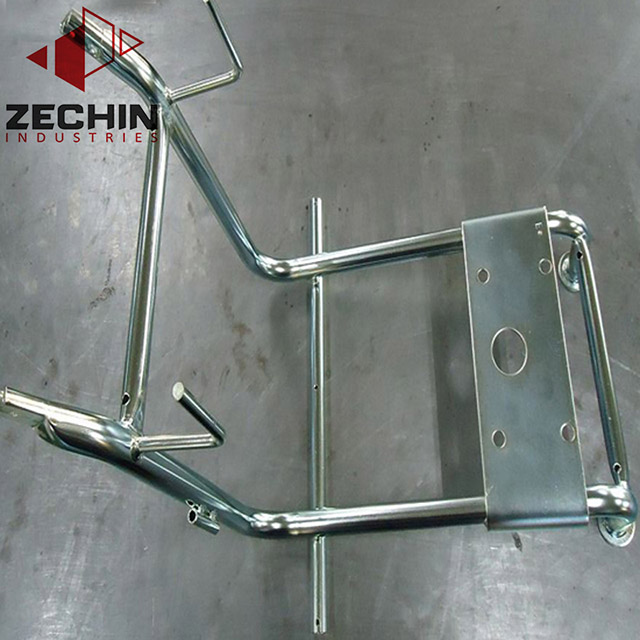

| Usage: | Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds: | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

| Mfg Process: | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance: | ±0.1MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| OEM: | Yes, can produce based on customer's drawings or samples. |

| Others: | Has own plastic injection department to produce plastic part to suit the metal products |

| Lead time: | 15-20days for mold and 30days for first lot. |

Surface Treatments

| Aluminum | Powder Coating, Brushing, Polishing, Sandblasting, Anodizing, PVD Plating, Nickel Plating, Chrome Plating, Bronze Plating, Copper Plating, Dacromet, Passivation |

| Stainless Steel | Polishing, Brushing, PVD Plating, Nickel Plating, Chrome Plating, Powder Coating |

| Carbon Steel | Powder Coating, Blackening, Baking Varnish, Dacromet, Zinc Plating, Hot Dip Galvanizing, Chrome Plating, Electrophoresis Coating, Enamel Painting, Heat Treatment etc. |

| Spring Steel | Powder Coating, Zinc Plating, Tin-plating, Heat Treatment, Nickel Plating etc. |

| Brass&Copper | Polishing, Brushing, Oil Injection, PVD Plating, Passivation etc. |

Any questions about our custom service, please feel free to contact us

We will reply in details within 8 hours

Your drawings are warmly welcomed

Product display

WHY CHOOSE US

1, Price

All the price quote will be calculated by engineers, then production manager check,and vice president check in the end, to ensure all prices reasonable

2,Quality

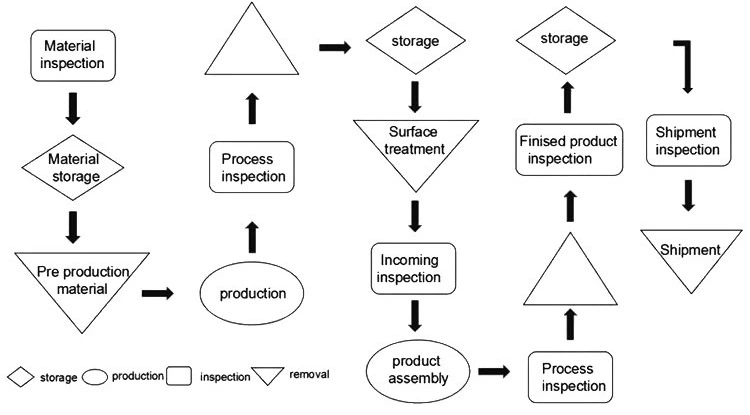

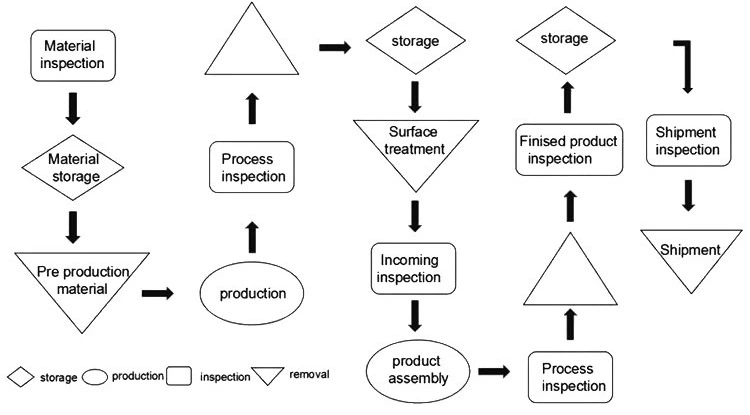

We have a team specialized in quality control, from the material coming, blanking ,production,surface,packing and before shipping, all steps will be run as our flow chart in order to control the quality.

3,Lead Time

We will make the production schedule once we get the confirmation,and each step will be strictly controlled by our production manager.And then the main leader to control all, in order to finish your goods on time.

4,Service

We offer 24-hour online service.Your any inquiries will be response in 8 hour.and we will spare no efforts to meet your reasonable requirements.

If you want to get much more information regarding tube bending,

you please feel free to contact with us as following at any time, we are 24 hours online!

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

Our advantage for metal fabrication

a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

| Materials: | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

| Usage: | Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds: | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

| Mfg Process: | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance: | ±0.1MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| OEM: | Yes, can produce based on customer's drawings or samples. |

| Others: | Has own plastic injection department to produce plastic part to suit the metal products |

| Lead time: | 15-20days for mold and 30days for first lot. |

Surface Treatments

| Aluminum | Powder Coating, Brushing, Polishing, Sandblasting, Anodizing, PVD Plating, Nickel Plating, Chrome Plating, Bronze Plating, Copper Plating, Dacromet, Passivation |

| Stainless Steel | Polishing, Brushing, PVD Plating, Nickel Plating, Chrome Plating, Powder Coating |

| Carbon Steel | Powder Coating, Blackening, Baking Varnish, Dacromet, Zinc Plating, Hot Dip Galvanizing, Chrome Plating, Electrophoresis Coating, Enamel Painting, Heat Treatment etc. |

| Spring Steel | Powder Coating, Zinc Plating, Tin-plating, Heat Treatment, Nickel Plating etc. |

| Brass&Copper | Polishing, Brushing, Oil Injection, PVD Plating, Passivation etc. |

Any questions about our custom service, please feel free to contact us

We will reply in details within 8 hours

Your drawings are warmly welcomed

Product display

WHY CHOOSE US

1, Price

All the price quote will be calculated by engineers, then production manager check,and vice president check in the end, to ensure all prices reasonable

2,Quality

We have a team specialized in quality control, from the material coming, blanking ,production,surface,packing and before shipping, all steps will be run as our flow chart in order to control the quality.

3,Lead Time

We will make the production schedule once we get the confirmation,and each step will be strictly controlled by our production manager.And then the main leader to control all, in order to finish your goods on time.

4,Service

We offer 24-hour online service.Your any inquiries will be response in 8 hour.and we will spare no efforts to meet your reasonable requirements.

If you want to get much more information regarding tube bending,

you please feel free to contact with us as following at any time, we are 24 hours online!

Cell: +86 158 5810 2851

SKYPE: steven.zheng89

Email: steven@zec-industrygroup.com